Language

- Home

- Equipment

- DN Pedal Spot Welding Machine

- DM Desktop Pedal Spot Welding Machine

- UN Butt Welding Machine

- DR Energy Storage Spot Welding Machine

- DNY Mobile Handheld Spot Welding Machine

- STUD Stud Spot Welding Machine

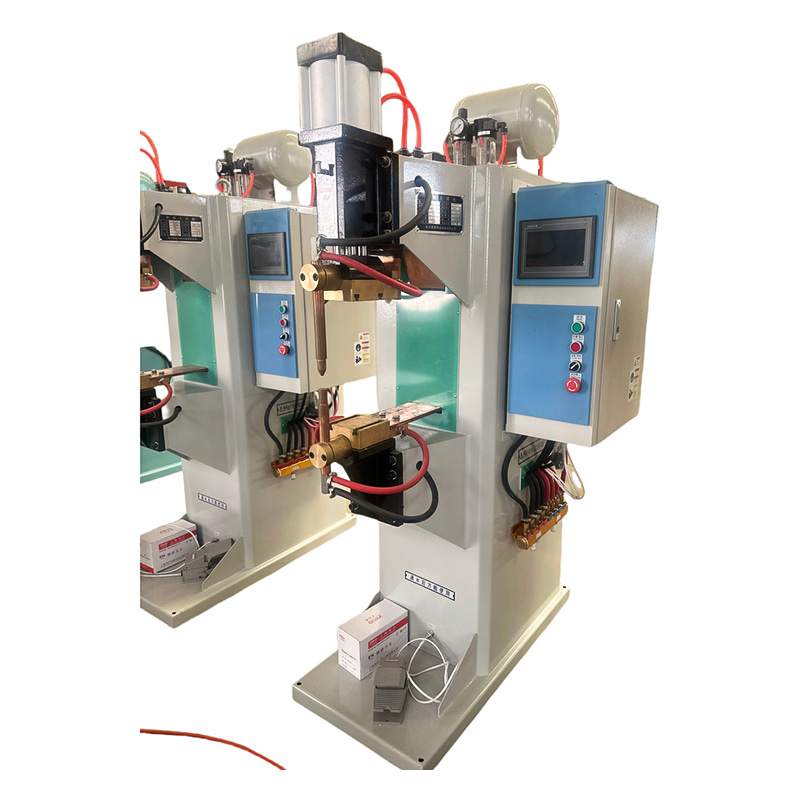

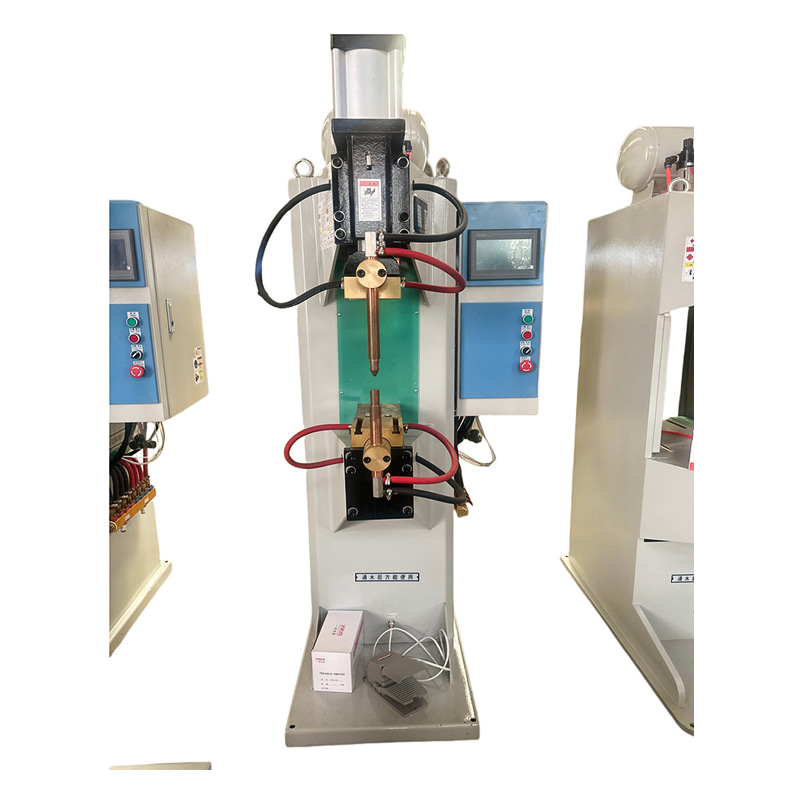

- DTN Pneumatic Spot Welding Machine

- DZN Mid Frequency Spot Welding Machine

- DBN Variable Frequency Spot Welding Machine

- FN Seam Welding Machine

- LSN Nut Conveyor

- Welding Robotic Arm

- Welding Accessories

- About

- Solutions

- Resources

- News

- Contact

Get A Quote