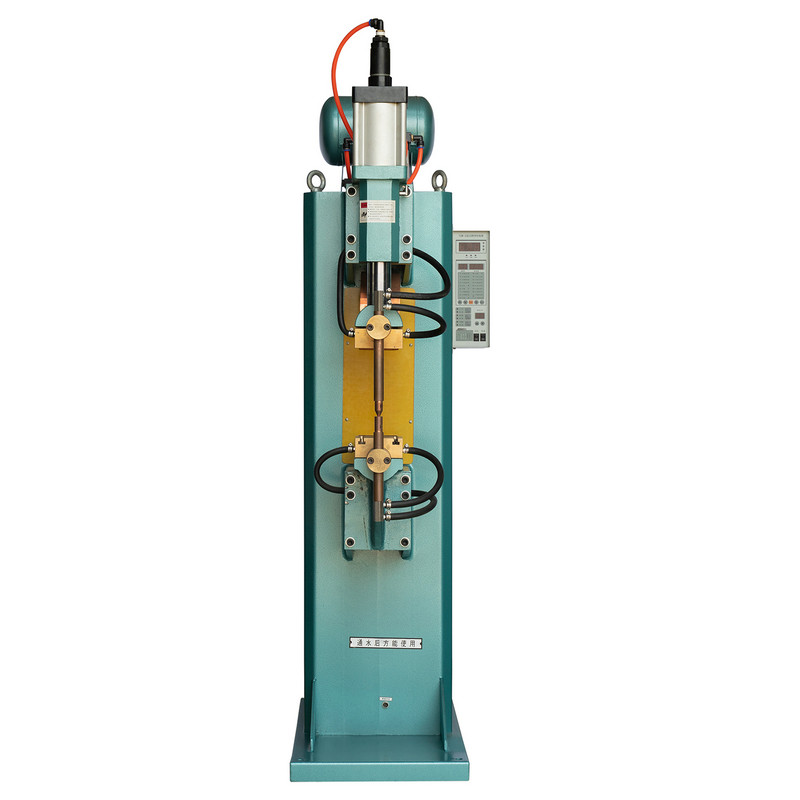

1. Metal shell and heat dissipation performance

DNY-16KW Spot Welding Machine generates a lot of heat during operation, which mainly comes from the resistance heat generated by the current passing through the workpiece and the electrode during welding. If the heat cannot be dissipated in time, it will cause the internal temperature of the spot welding machine to rise, which will affect its performance and stability. The metal shell plays a vital role in this regard.

High thermal conductivity: Metals, especially materials commonly used in the DNY-16KW Spot Welding Machine shell, such as aluminum alloy and stainless steel, have high thermal conductivity. This means that the metal shell can quickly conduct the heat generated inside the spot welding machine to the surface of the shell, and dissipate the heat to the environment through natural convection or forced cooling (such as fans, water cooling, etc.).

Heat dissipation area: Metal shells are usually designed with a larger surface area to provide more heat dissipation area. This helps to speed up the heat dissipation, thereby reducing the temperature inside the spot welding machine and maintaining the stability of its working state.

Heat radiation: The metal shell can also transfer heat to the surrounding environment by heat radiation. Especially in high temperature environment, the heat radiation effect of metal shell is particularly significant, which helps to further reduce the temperature inside the spot welder.

2. Metal shell and electromagnetic compatibility

DNY-16KW Spot Welding Machine will generate a strong electromagnetic field when working, which may interfere with surrounding electronic equipment. Metal shell plays an important role in electromagnetic compatibility.

Electromagnetic shielding: The metal shell can provide a continuous electromagnetic shielding layer, effectively blocking or weakening the interference of the electromagnetic field generated by the spot welder to the external environment. This helps to protect the surrounding electronic equipment from electromagnetic interference and ensure their normal operation.

Grounding protection: The metal shell is usually connected to the grounding system of the spot welder, which not only provides additional safety protection (such as preventing electric shock), but also helps to guide the static charge and electromagnetic interference generated by the spot welder to the ground, further reducing interference with the external environment.

3. Metal shell and mechanical strength

While providing heat dissipation and electromagnetic shielding, the metal shell also gives the spot welder a higher mechanical strength.

Impact resistance: The metal shell has high hardness and toughness, and can resist external forces such as collisions and impacts that may be encountered during use. This helps protect the electronic components and mechanical structures inside the spot welding machine from damage and prolongs its service life.

Corrosion resistance: The high-quality metal casing can be improved by proper surface treatment (such as galvanizing, plastic spraying, etc.) to improve its corrosion resistance. This helps prevent the corrosion of the casing caused by environmental factors such as moisture and salt spray, and keeps the appearance of the spot welding machine neat and stable.

4. Metal casing and aesthetics and durability

In addition to the above functions, the metal casing also gives the spot welding machine good aesthetics and durability.

Appearance design: The metal casing usually adopts a streamlined design or a modern and simple style, which makes the DNY-16KW Spot Welding Machine more beautiful and generous in appearance. This helps to enhance the user's visual experience and satisfaction.

Durability: The metal casing has high wear resistance and anti-aging properties, and can maintain a neat and beautiful appearance during long-term use. At the same time, the metal casing also has good anti-deformation ability, and can maintain the stability of its shape and structure even in harsh use environments.