In the ever-evolving world of industrial technology, finding the right equipment to meet your welding needs can be a challenging task. With countless machines on the market, each claiming superiority, how do you know which one truly stands out? Could it be the REINFORCED BUTT WELDING MACHINE, a device designed to redefine the boundaries of high-strength welding?

Let's delve into the specifications and features of this remarkable welding machine to understand what sets it apart. The REINFORCED BUTT WELDING MACHINE boasts an impressive array of capabilities that cater to a wide range of industries, from automotive and aerospace to construction and manufacturing. Its robust design ensures durability and reliability, even under the most demanding conditions.

One of the standout features of this machine is its advanced welding technology. Utilizing state-of-the-art welding processes, the REINFORCED BUTT WELDING MACHINE is capable of producing seamless, high-quality welds that meet even the strictest standards. This precision is achieved through a combination of precise control systems and high-performance welding electrodes, ensuring consistent results across various materials and thicknesses.

Moreover, the REINFORCED BUTT WELDING MACHINE is equipped with user-friendly controls that cater to both novice and experienced welders alike. The intuitive interface allows operators to easily adjust welding parameters such as current, voltage, and welding speed, enabling them to tailor the welding process to their specific needs. This flexibility is crucial in diverse industrial settings where different welding requirements may arise.

Safety is another paramount concern in welding operations. The REINFORCED BUTT WELDING MACHINE addresses this by incorporating advanced safety features that protect both the operator and the surrounding environment. These include features such as automatic shut-off in the event of overheating, emergency stop buttons, and robust shielding to prevent arc flash and sparks. With these safeguards in place, users can perform welding tasks with peace of mind.

Efficiency and productivity are also key factors in modern industrial operations. The REINFORCED BUTT WELDING MACHINE excels in this regard by offering rapid cycle times and minimal downtime. Its robust design ensures that maintenance requirements are kept to a minimum, allowing the machine to run smoothly for extended periods without the need for frequent repairs or replacements. This contributes to higher overall productivity and lower operational costs.

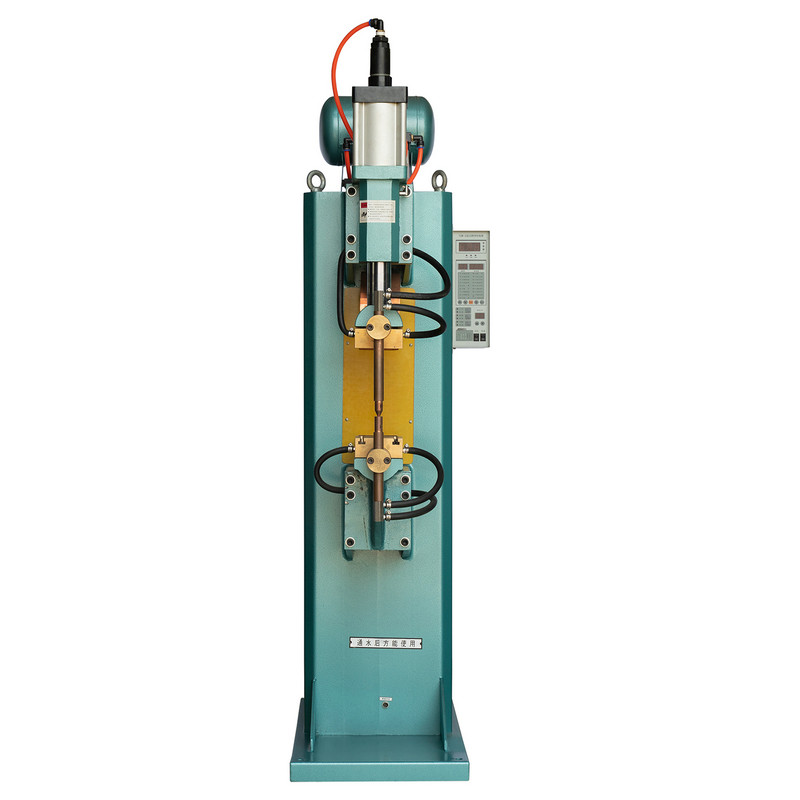

Looking at the images accompanying this article, it's easy to see the sheer size and power of the REINFORCED BUTT WELDING MACHINE. Its imposing presence hints at the capability to handle even the largest and most challenging welding projects. The machine's components are meticulously engineered to ensure precision and durability, with every detail carefully considered to maximize performance.

In addition to its technical specifications, the REINFORCED BUTT WELDING MACHINE also offers versatility in terms of material compatibility. It can be used to weld a wide range of metals, including steel, stainless steel, aluminum, and nickel alloys. This makes it an ideal choice for industries that work with a variety of materials, as it eliminates the need for multiple welding machines.

As we continue to push the boundaries of innovation in the industrial sector, the REINFORCED BUTT WELDING MACHINE emerges as a standout option for high-strength welding applications. Its combination of advanced technology, user-friendly controls, safety features, and versatility makes it a valuable asset for any business looking to improve its welding capabilities.