Welding process

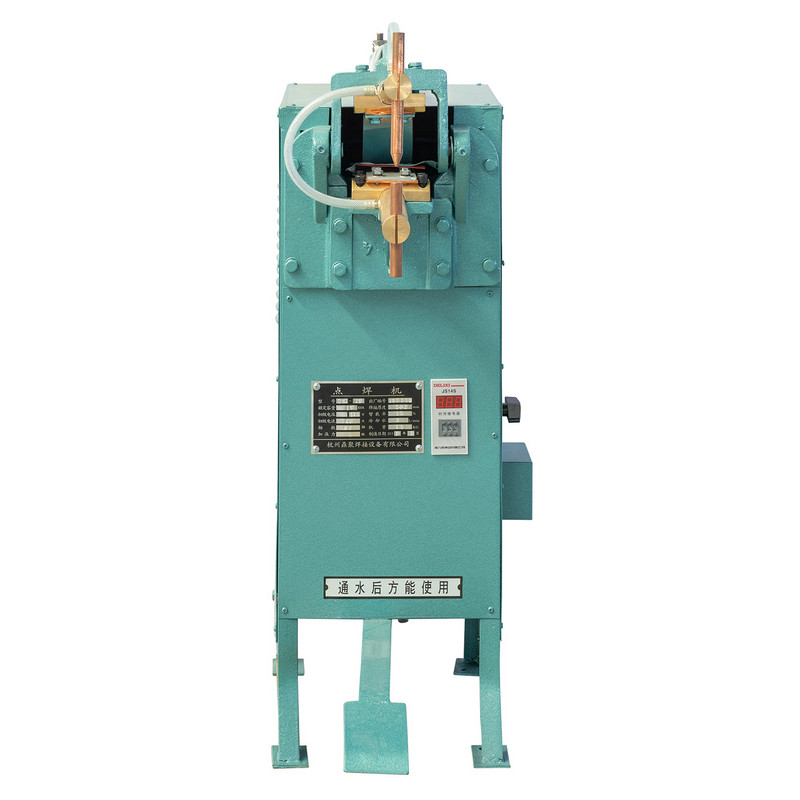

DN pedal spot welding machine adopts resistance welding process, which is a technology that uses heat generated by electric current to weld metal materials. During welding, the current flows through the contact points of the two pieces of metal to be welded, and the heat generated by the resistance causes the temperature of the contact points to rise rapidly until the material reaches a molten state. At this time, the welder applies a certain amount of pressure to press the molten metal together to form a firm welded joint.

This welding process has many advantages. First, it can achieve welding in a very short time, with a fast welding speed, and can usually reach an efficiency of dozens of welds per minute. This is particularly important for industrial environments that require high-efficiency production, such as automobile manufacturing and home appliance production. Secondly, the resistance welding process can ensure the strength and stability of the welded joint, because in the molten state, the molecular structure of the metal material will rearrange to form a tighter bond.

In addition, the DN pedal spot welding machine has good adjustability in terms of current and welding time. The operator can adjust the current size and welding time according to specific welding needs to achieve the best welding effect. Such flexibility enables DN welders to adapt to different welding tasks and ensure that welded joints meet various strength requirements.

Material adaptability

Another important factor that makes DN pedal spot welding machines widely recognized is their excellent material adaptability. DN pedal spot welding machine can handle a variety of metal materials, such as carbon steel, stainless steel and aluminum alloys. These materials have different requirements for welding strength during welding, so DN welders can meet the welding needs of different materials by adjusting welding parameters.

For carbon steel, DN pedal spot welding machines can use higher current and moderate welding time to achieve good welding results, because carbon steel has a lower melting temperature and is relatively easy to weld. For alloy materials such as stainless steel, the welding process requires more delicate control to prevent the heat affected zone from being too large and causing material properties to deteriorate. DN pedal spot welding machines can maintain the strength and corrosion resistance of welded joints by reducing welding current and shortening welding time.

Aluminum alloys require special treatment when welding due to their good thermal conductivity and low melting point. The flexibility of DN welders enables operators to adjust welding parameters according to the characteristics of aluminum alloys to achieve the best welding results.